He has been a manager and an auditor with Deloitte, a big 4 accountancy firm, and holds a degree from Loughborough University. If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm. The agency can then compensate for this loss by charging their clients this higher rate.

How To Calculate Predetermined Overhead Rate

- There are a number of factors that go into calculating a predetermined overhead rate.

- If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

- Since the numerator and denominator of the POHR formula are comprised of estimates, there is a possibility that the result will not be close to the actual overhead rate.

- Using this calculation gives the best possible estimation of costs based on relatively comfortable overhead estimations.

- JKL allocates the manufacturing overhead based on the normal and expected number of production machine hours which are 20,000 for the new year.

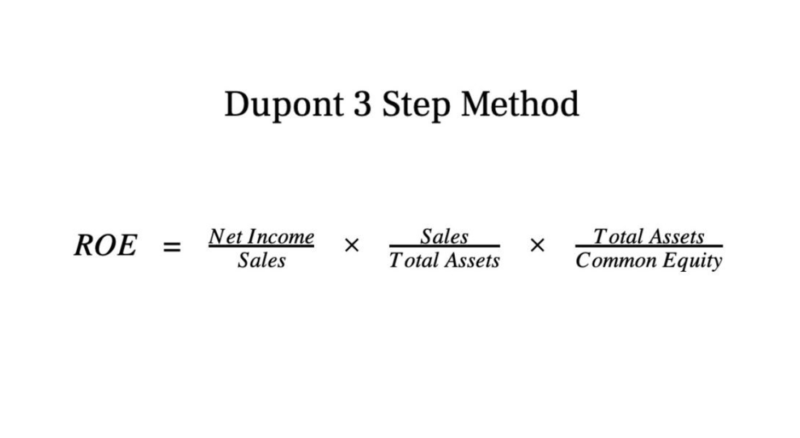

- The predetermined overhead rate formula is calculated by dividing the total estimated overhead costs for the period by the estimated activity base.

The rate is configured by dividing the assumed overhead amount for a particular period by a certain activity base. Following are some of the disadvantages of using a predetermined overhead rate. Let’s say we want to calculate the overhead cost of a homemade candle ecommerce business.

How do I know if a cost is overhead or not?

- The manufacturing overhead costs are applied to the product based on the actual number of activity base units used during the accounting period.

- Again, that means this business will incur $8 of overhead costs for every hour of activity.

- If a job in work in process has recorded actual labor costs of 6,000 for the accounting period then the predetermined overhead applied to the job is calculated as follows.

- However, modern absorption requires the use of multiple bases to enhance the accuracy of the process.

- It can help manufacturers know when to review their spending more closely, in order to protect their business’s profit margins.

- The example shown above is known as the single predetermined overhead rate or plant-wide overhead rate.

It involves estimating the total cost of producing goods and services, then dividing it by either direct labor hours or machine hours used in production. Knowing your predetermined overhead rate helps you plan and control future expenditures effectively, improving efficiency and profitability for your business. With this normal balance information in mind, it pays to take some time to calculate your own predetermined overhead rate so that you can manage expenses with confidence. In simple words, complex manufacturing is not limited to the usage of direct material and direct labor, but the use of overheads has increased significantly.

How to Sell on Walmart Marketplace & Grow Your Ecommerce Business

Before the beginning of any accounting year, it is determined https://www.bookstime.com/articles/small-businesses-bookkeeping to estimate the level of activity and the amount of overhead required to allocate the same. At a later stage, when the actual expenses are known, the difference between that allocated overhead and the actual expense is adjusted. A predetermined overhead rate is an allocation rate that is used to apply the estimated cost of manufacturing overhead to cost objects for a specific reporting period.

Predetermined Overhead Rate Calculation (Step by Step)

It’s calculated by dividing the estimated cost of overheads by the estimated/budgeted level of activity. It’s useful in cost accounting as product costing can only be obtained once overheads are absorbed in the cost of the product. The formula for a predetermined overhead rate is expressed as a ratio of the estimated amount of manufacturing overhead to be incurred in a period to the estimated activity base for the period. In a company, the management wants to calculate the predetermined overhead to set aside some amount for the allocation of a cost unit. Therefore, they use labor hours for the apportionment of their manufacturing cost. There are a number of factors that go into calculating a predetermined overhead rate.

In order to calculate the predetermined overhead rate for the coming period, the total manufacturing costs of $400,000 is divided by the estimated 20,000 direct labor hours. If a job is in work in process and has recorded actual direct labor hours of 600 during an accounting period then the predetermined overhead applied to the job is calculated as follows. The manufacturing overhead costs are applied to the product based on the actual number of activity base units used during the accounting period.

The predetermined rate is based on estimates before the accounting predetermined overhead rate period begins and is held constant throughout the period. The most prominent concern of this rate is that it is not realistic being that it is based on estimates. Since the numerator and denominator of the POHR formula are comprised of estimates, there is a possibility that the result will not be close to the actual overhead rate. The fact is production has not taken place and is completely based on previous accounting records or forecasts. Additionally, you should recalculate your predetermined overhead rate any time there is a significant change in your business, such as the addition of new equipment or a change in your product line.